New STADLER facility supports North America’s shift toward automated recycling

The European company is bringing decades of recycling insight to the U.S. market

What happens when a European recycling pioneer sets its sights on North America? STADLER, recognized globally for its advanced recycling technology and waste management systems, is bringing German precision to the southern U.S.

After centuries of evolving operations, the company is breaking ground on a new operations complex in North Carolina. This strategic foray into a rapidly growing market highlights STADLER's dedication to revolutionizing recycling on a global scale.

The evolution of STADLER's business model

The first iteration of STADLER was in 1791 as a blacksmith shop in Germany. Over centuries, the company has maintained its status as a family-owned and operated business, now under the leadership of its seventh generation with the eighth generation poised to continue involvement. This legacy positions STADLER as one of Germany's 50 oldest continuously operating companies.

The company's venture into recycling began in the 1970s, driven by an opportunity to design specialized waste collection containers for the 1972 Munich Olympics. The leadership at STADLER identified recycling as a niche industry with immense potential. By the late 1980s, the company had developed its first full recycling facility, and, in 1991, introduced the ballistic separator — a groundbreaking innovation that remains a cornerstone of modern waste management technology.

Throughout the 1990s, STADLER expanded its capabilities, including steelwork manufacturing and turnkey installation services. By 2014, growing global demand for its recycling solutions led to the establishment of a modern manufacturing headquarters in Altshausen, Germany, which has since undergone four expansions to accommodate continued growth.

Strategic expansion: why North America and why now?

In 2016, STADLER identified North America as a market ready for advanced automation in recycling. Recycling systems in the U.S. still relied heavily on manual processes, unlike in Europe where automation had already become the norm due to the high cost of labour.

STADLER's leadership recognized this moment as an opportunity to introduce its highly automated recycling solutions, honed through decades of innovation in Europe. By aligning their expertise with this growing demand for efficiency, STADLER was poised to fill a critical gap in the market.

The decision to establish an operations complex in North Carolina was both strategic and practical. The location, specifically the Winston-Salem, Colfax, and Greensboro area, is located near three major ports. It sits at the intersection of two of the largest highways in the U.S. — Interstate 40 and Interstate 95 — making it a logistical hub for road shipments. This accessibility is a significant advantage for importing goods from Europe, sourcing stock parts, and distributing products efficiently to customers across North America.

Beyond logistics, the region boasts a highly skilled labour pool rooted in a legacy of craftsmanship. Historically home to the textile and furniture industries, the area has a workforce rich in second- and third-generation skilled labourers. By situating its hub in North Carolina, STADLER has created a strategic radius for efficient operations, primarily focused on the East Coast and stretching into the Midwest and other regions. This approach ensures that the company can deploy both human and capital assets effectively within these areas, maintaining a high standard of customer support.

Tackling North America's unique recycling challenges

The size and diversity of the North American market present unique challenges for STADLER as it expands. In Europe, markets are denser and more uniform, but the geography of the U.S. and Canada creates logistical hurdles. With population centres spread across vast distances, the transportation of recycled materials can often negate the environmental benefits of recycling, creating an inherent tension between environmental goals and economic practicality.

Adding to this complexity is the diversity of regulatory environments across states and municipalities. The United States alone operates under a patchwork of local, state, and federal rules, making it more than just one market. This lack of standardization requires tailored solutions that can adapt to the specific needs of each region while maintaining overall efficiency.

STADLER's adaptive growth strategy

STADLER addresses these challenges with a multi-faceted approach that combines technological innovation, collaboration, and customer empowerment. Recognizing that no single company can excel at everything, the company focuses on its core strengths — technologies like its drum screens and ballistic separators — while partnering with other providers to integrate a wide range of solutions into its systems.

STADLER also extends its involvement further into the recycling cycle. Beyond capturing and processing materials, the company now collaborates with secondary processors to improve the quality of recycled outputs. Innovations like refining wash and extrusion lines help produce materials that meet higher standards for reuse, enabling the creation of new products such as thermoforms for bottles.

Education is another pillar of STADLER's approach. Through partnerships with universities and outreach to young engineers, the company is actively fostering interest in the recycling industry. By equipping the next generation of professionals with knowledge and excitement for the field, STADLER is investing in the long-term growth of the sector.

But at the foundation of these strategies is STADLER's commitment to hearing the concerns and needs of its customer base. STADLER prides itself on being a partner to the industry, fostering open communication with customers to understand their pain points and emerging challenges. By staying connected to industry-specific media and maintaining regular dialogues with stakeholders, STADLER identifies opportunities and uncovers problems that need innovative solutions.

This customer-centric approach has informed STADLER's growth strategy in North America. Here, the focus has been on building trust and relationships, leveraging feedback from customers to design solutions tailored to the region's specific needs.

"It all starts with listening," says Mat Everhart, CEO of STADLER America. "We ask a lot of questions and take the time to listen to our customers. This approach helps us better understand their needs and deliver solutions that make a real difference. And honestly, as simple as that sounds, I think it's the best thing we can possibly be doing."

Connecting with STADLER's data-driven solutions

A cornerstone of STADLER's 21st century strategy is its emphasis on data-driven solutions. While its mechanical systems remain foundational, STADLER's latest focus is on digital innovation.

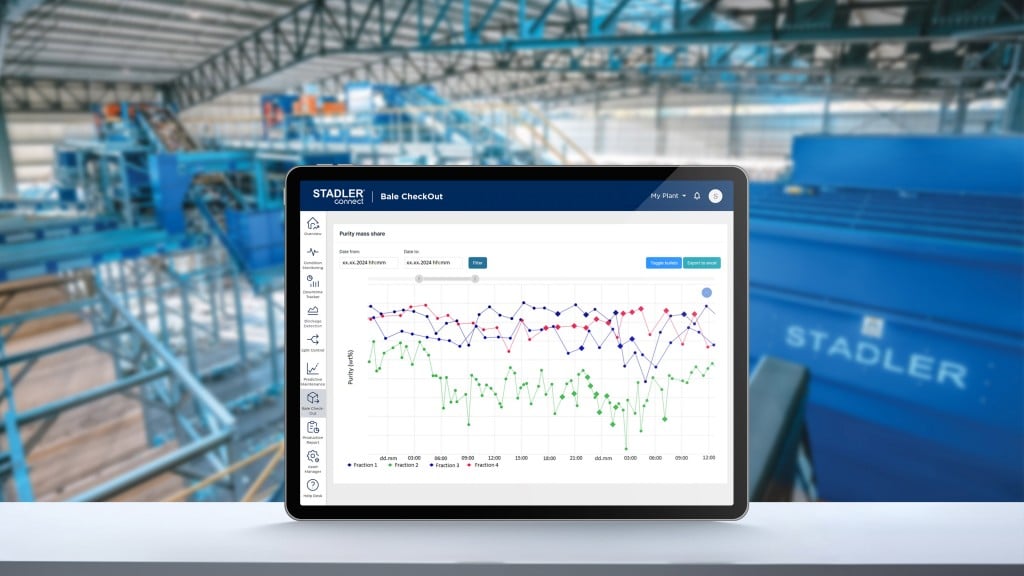

Central to this effort is STADLERconnect, a cutting-edge digital platform designed to provide customers with actionable data to optimize their facilities. Traditional recycling plants may struggle with inefficiencies due to a lack of visibility into real-time operations.

STADLERconnect addresses this gap by integrating materials analysis, predictive maintenance, and process automation into a single, user-friendly interface. Customers can monitor their plant's performance, detect potential blockages before they cause downtime, and even adjust conveyor systems to improve capacity utilization.

STADLER is also introducing enhanced sensor technologies, including near-infrared (NIR) systems, to perform detailed composition analyses of materials throughout the plant. This provides operators with a clearer picture of what is coming in and out of their facility, enabling them to make informed decisions that maximize throughput and improve the purity of recovered materials.

"These are things nobody else is doing, and so far, with our customers, it's just been sort of an ‘aha moment,'" says Everhart. "The plants that they thought couldn't possibly do any more are doing 10 to 15 percent more at a better purity and a better uptime level. And for plants that are struggling to find ways to get all the tons through the door and still meet quality, that can be a game changer."

The smart technologies implemented by STADLER are designed to improve efficiency and future-proof facilities against evolving waste streams and market demands.

Planned expansion across North America

STADLER's North Carolina facility is designed with future growth in mind, built to accommodate market demands over the next 15 years. The facility provides the space and infrastructure necessary to support a growing customer base and enable STADLER to expand its human capital and technical capabilities.

This forward-thinking approach allows the company to respond to the needs of a dynamic market while ensuring that it can meet the increasing demand for parts, services, and expertise.

As the North American market continues to evolve, STADLER sees potential for further expansion, including additional facilities across the continent. These expansions will be strategically located to enhance service delivery and decrease response times, particularly in areas where market demand justifies additional investment. By maintaining flexibility in its plans, STADLER can adapt to changes in market conditions and customer needs, ensuring that its growth aligns with the broader goals of the recycling industry.