New digital recycling plant optimization solutions from STADLER

Through the cloud-based platform STADLERconnect, the company offers a single-access-point solution for its digital products

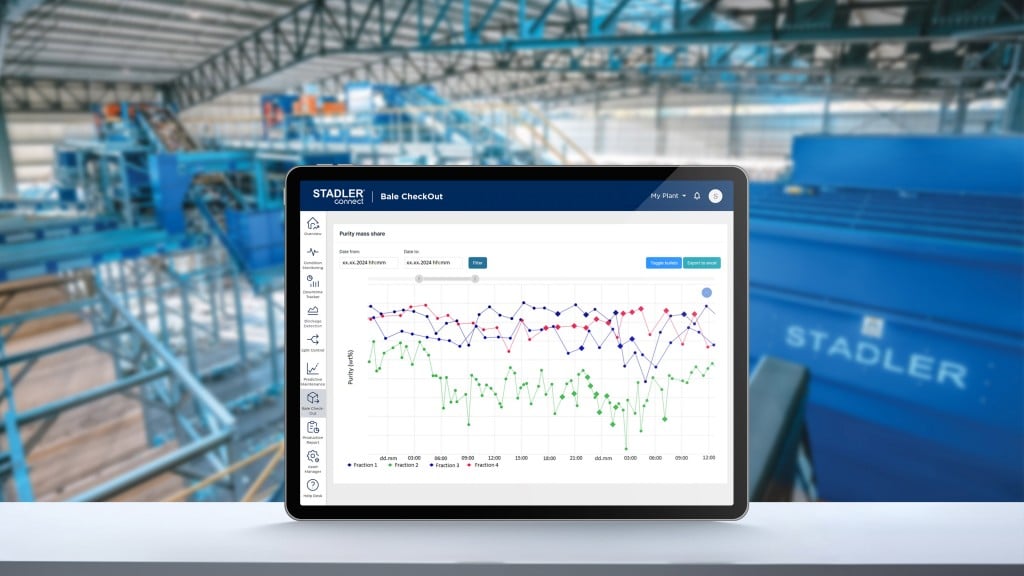

STADLER is taking aim at transforming recycling plant efficiency with new digital solutions specifically tailored for sorting plants with a focus on optimizing operations. The comprehensive cloud-based STADLERconnect platform offers recycling and sorting plants a single-access-point solution for its digital products, helping them unlock the full potential of machine and material data "to drive impactful operational improvements".

The new digital tool is designed to customize views for both operators and management. "At STADLER, we view digital solutions as crucial for maximizing the performance of recycling plants, positioning them as a core part of our innovation leadership," says Julia Stadler, chief digital officer at STADER. "Our strategy centres on sustaining our role as the market leader and a pioneer in designing and building turnkey recycling facilities."

Avoiding downtime with predictive maintenance

Predictive maintenance, one of the STADLERconnect modules, enables a proactive approach to equipment maintenance with the help of sensors, providing operators with instant alerts on any critical changes in sensor data before potential issues arise. This early warning capability allows for immediate inspections, minimizing costly production delays and reducing the risk of sudden breakdowns.

Andreas Stöcker, deputy operations manager at REILING, has seen notable benefits with this system. "The installation of Predictive Maintenance resulted in easier maintenance and allowed for forward-thinking planning of service work, as every small change to the machine is immediately reported. Before we decided on this solution, some bearing damage would occur very suddenly. With the measuring system, we can prevent this issue from happening. From the short time we have been using the measuring system, I can say that it should be installed on every machine from the beginning, although, including it subsequently makes sense as well."

In developing its digital solutions, STADLER has pursued two objectives: delivering added value by using key data insights to enhance plant operations, and applying these insights to improve both plant design and after-sales service.

"Our digital solutions are purpose-built for sorting plants, directly addressing the needs of plant operators," says Julia Stadler. "Leveraging our extensive OEM expertise, we ensure greater accuracy in areas such as determining conveyor equipment status. Our team combines software development and engineering expertise. This approach goes beyond simple data collection and visualization: our solutions leverage new and existing data points to drive meaningful operational improvements."

Maximizing plant performance with data-driven tools

STADLER's portfolio of digital solutions can be accessed through STADLERconnect. This cloud-based platform harnesses machine and material data to maximize the availability, performance, and overall process efficiency of sorting plants. Powered by real-time plant data and AI, STADLERconnect is an integrated solution that adapts to varied plant configurations and needs. It focuses on two core areas.

The first area is centred around machine data and includes four modules:

- Predictive Maintenance: Prevents equipment breakdown

- Blockage Detection: Automatically alerts operators as blockages occur

- Downtime Tracker: Identifies and analyses plant downtimes

- Support Portal: Facilitates communication with after-sales service

The second area is focused on material data and encompasses:

- Material Split Control: Equally distributes material flows to improve performance

- Production Report: Visualizes production data, and in particular material output

- BaleCheckIn: Analyzes material infeed at the bale-specific level

- BaleCheckOut: Analyzes material output at the bale-specific level

"STADLERconnect's digital tools leverage AI and intelligent processing of material and machine data to optimize plant performance across key areas," says Dr. Xiaozheng Chen, material analysis and AI specialist at STADLER. "The modules work together to create a seamless flow of information, enhancing plant reliability and supporting operators at every stage — from tracking material quality in real time to automatically controlling processing steps and predicting maintenance needs — all designed to deliver maximum value to our customers."

By automating various parts of the plant, STADLERconnect improves operational performance while reducing the workload for operators. STADLER's material analysis tools increase transparency on both quantity and quality. This enables consistent product quality while reducing the need for costly manual quality checks. Additionally, the company's digital maintenance solutions make service events more predictable and enable rapid responses to unforeseen issues, minimizing downtime.

"Through STADLERconnect we provide a unified platform that integrates data from multiple plants and data sources, offering the plant management a centralized, remote overview of all facilities," explains Julia Stadler. "Our data-driven insights help improve key performance indicators (KPIs), for example by identifying and addressing frequent downtime causes or by avoiding blockages that lead to plant stoppages."

Continuous innovation for a smart sorting revolution

STADLERconnect is designed to adapt to the evolving needs of recyclers, with regular updates, and feature and security enhancements to all modules provided at no additional cost to customers.

"The patented STADLERconnect modules have been successfully implemented in several plants, says Stadler. "The next phase of the platform's deployment is its rollout across STADLER turnkey recycling plants worldwide. We are expanding our portfolio with new modules, such as Windshifter Automation and Infeed Decision Aid, which will be available soon. Additionally, we are not only focusing on integrating data from our own equipment: as an integrator, we are in a unique position to aggregate data from all the equipment in our plants. This will be the next significant step for STADLERconnect. Our ultimate aim is to implement a truly smart sorting plant."