Machinex delivers fully automated plastics sorting system for PureCycle facility

Machinex’s optical sorters and sorting robots reduce the need for manual labour in the multi-grade plastics recycling plant

Machinex has produced a 100 percent automated plastics sorting system for PureCycle Technologies' Denver, Pennsylvania facility. PureCycle's polypropylene recycling technology transforms polypropylene into ultra-pure recycled resin, enabling it to be used multiple times as a renewable resource. The new facility has the capacity to process 10 metric tons per hour, relying on zero manual sorters.

"Partnering with PureCycle represents a strategic advancement for Machinex in our efforts to advance the plastics recycling landscape," says Chris Hawn, CEO of Machinex Technologies. "This collaboration showcases the performance of our sorting technologies in a high-demanding application, specifically in multi-grade plastics recycling. We appreciate the trust PureCycle placed in us to complete this project, and are proud to witness them achieve their results as expected."

Efficiently removing contaminants and boosting purity

Pure Cycle needed an advanced system to efficiently remove contaminants and sort polypropylene (PP) from bales, containing PP as well as other high-value materials such as high-density polyethylene (HDPE), and polyethylene terephthalate (PET) purchased from other material recovery facilities (MRFs), or post-industrial PP plants. With a preference of at least 90 percent purity for their PP bales, the purchased bales are typically found to be below this threshold, says the company.

Pure Cycle decided to partner with Machinex due to their expertise in plastic sorting. Machinex's Mach Hyspec optical sorters and SamurAI sorting robots significantly reduce the need for manual labour.

"It was great to work with Machinex on the development of our first regional pre-processing (PreP) facility," says PureCycle's CEO, Dustin Olson. The Machinex technology and their team helped to quickly turn it into a professional, efficient PreP operation. Most importantly, it has allowed us to feed our flagship purification facility in Ohio with a more pure feedstock stream."

Specialized sorting equipment facilitating a circular economy for plastics

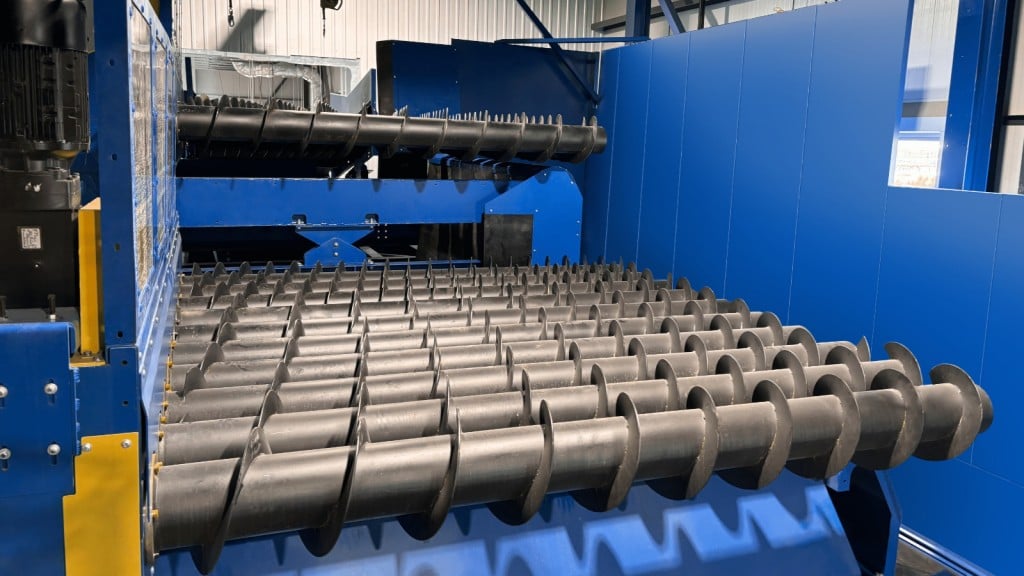

The equipment being utilized for this pre-processing (PreP) facility consists of four MACH Hyspec optical sorters, two II-RAM Balers, two SamurAI sorting robots, an Eddy Current, a magnet, and a Mach trommel. Additionally, the MACH IntellTM business intelligence platforms installed on the SamurAI robots are being used to provide essential data gathering and reporting, optimizing the performance of equipment. Once the HDPE and PET are sorted out of their material stream, PureCycle can sell those commodities to be used by other recyclers.

The companies say this collaboration not only underscores Machinex's commitment to providing cutting-edge sorting solutions, but also supports PureCycle's mission to create a sustainable circular economy for plastics.