Machinex's new screw screen reduces tonnage sent to manual presort, enhancing worker safety

The modular MACH Screw Screen works in tandem with the MACH Trommel to expand the company’s presort solutions portfolio

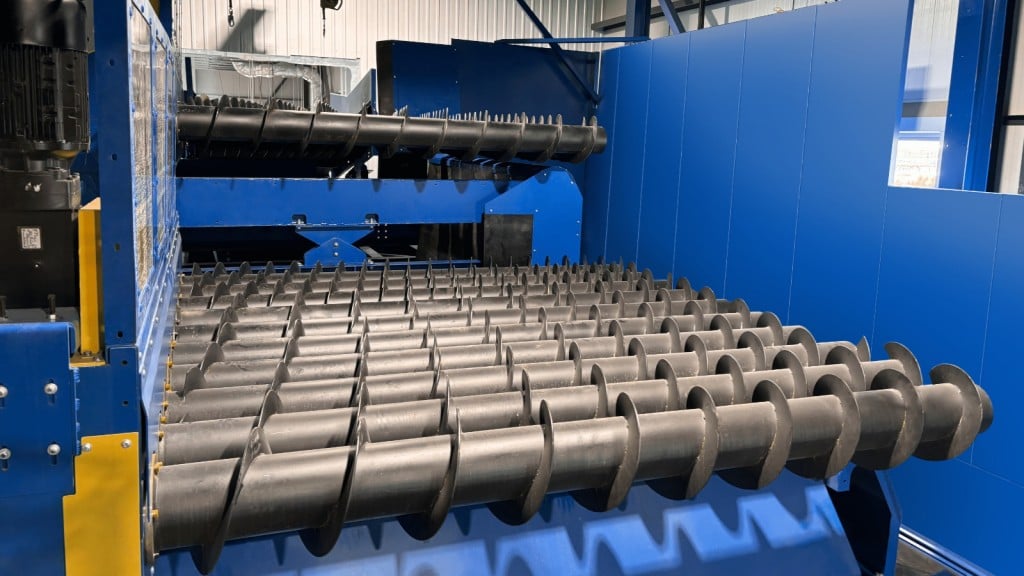

Machinex has introduced the MACH Screw Screen to its front-end equipment line. The new screw screen works with the company's MACH Trommel to expand the company's mechanical presort solutions offerings for custom material recovery facilities (MRFs).

The MACH Screw Screen is designed to separate materials by size, whether at presort or screening (OCC & scalping). Its primary function is to reduce the tonnage sent to manual presort, while also enhancing worker safety by removing small hazardous materials.

Two patent-pending innovations

The modularity of this equipment makes it a valuable asset for MRFs in the long term. The independent angle adjustments on both decks, considering the tilt and the roll of the screws, is a patent-pending new innovation.

Additionally, the double-flight design, which is also patent pending, protects the equipment from long parts falling through the screws. The number of screws are adjustable to meet client requirements and changing consumer habits. The new MACH Screw Screen is engineered to optimize sorting efficiency and accelerate operations.

An expanded mechanical front-end solution

The MACH Screw Screen is the second piece of mechanical front-end equipment designed by the company, adapted for single-stream, mixed waste processing and industrial, commercial, and institutional (C&I) systems. The first, the MACH Trommel, is a reliable piece of equipment adapted for those same three types of systems but has also proven to be efficient in construction and demolition (C&D) as well as organic waste sorting systems. Each offers its own unique features and advantages, in terms of footprint and flexibility of screening size adjustments.

Machinex's goal in the waste and recycling market is to design, manufacture, and support its own equipment. Machinex customers now have an opportunity to evaluate the best solutions for their application, which can be manufactured and supported by one company.