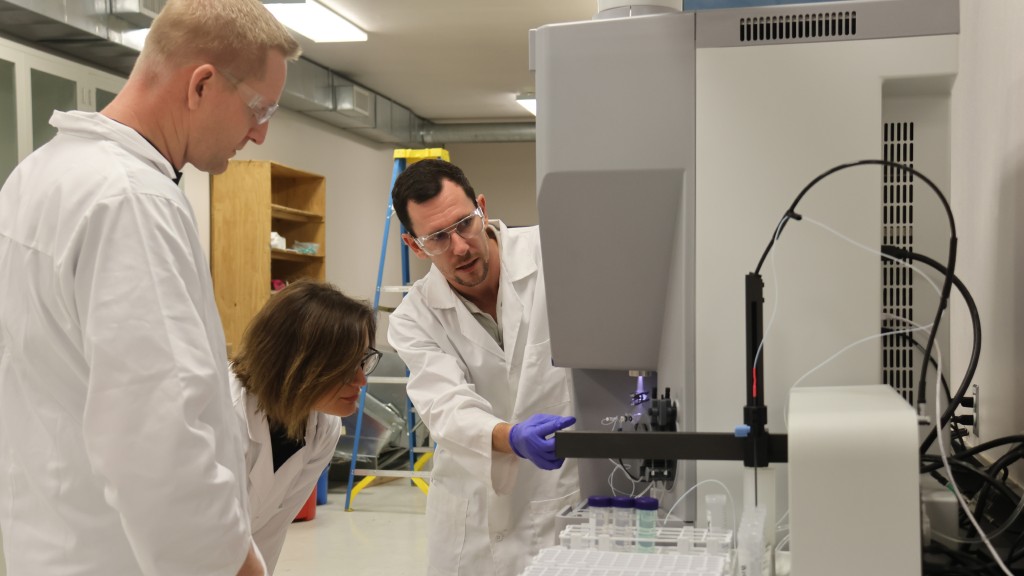

DOE supports development of reclaimed carbon anode material for batteries

C-BATT’s breakthrough material, Obsidia, is derived from mining waste, stores much more lithium per gram than graphite, and is more sustainable

The U.S. Department of Energy (DOE) plans to award $1 million to support the development and scale-up of C-BATT's breakthrough anode material, Obsidia.

The focus of the project is to optimize the incorporation of reclaimed carbon derived from mining waste into the anode material, further improving its sustainability profile, and to advance the Obsidia manufacturing process to accelerate commercial availability of this key domestically-produced battery material.

"As our team is working diligently to make the final tweaks to baseline Obsidia ahead of wide sampling, this award will enable us to continue to improve the sustainability profile of our product and progress toward manufacturing at scale," says Bill Easter, president of C-BATT.

Obsidia processing and manufacturing

Obsidia is domestically sourced and produced, has the promise of being one of the most economically viable graphite-replacing anode materials, and stores much more lithium per gram than graphite with an even lower carbon footprint, says the company.

The C-Batt project will accelerate the transition of Obsidia manufacturing from batch processing to semi-continuous processing, enabling improvements in production cost and time. Based on years of proven polymer-derived ceramic chemistry, the manufacture of Obsidia lends itself to industrial scaling because its components are chemically mixed and prepared, rather than having to be grown via chemical vapor deposition or constructed at the nanoscale on carefully crafted microscopic frameworks. This will allow C-BATT to scale faster to larger quantities, while keeping the capital costs and complexity of its factories low.

Dr. Rudy Olson, C-BATT's vice president of technology and one of the principal investigators on the project, said, "We are excited to begin tackling the challenges of scaling up the production of this revolutionary product."