Green Li-ion opens North American facility to produce recycled lithium-ion battery materials

Oklahoma-based plant will produce battery-grade cathode precursor, lithium, and anode materials from black mass

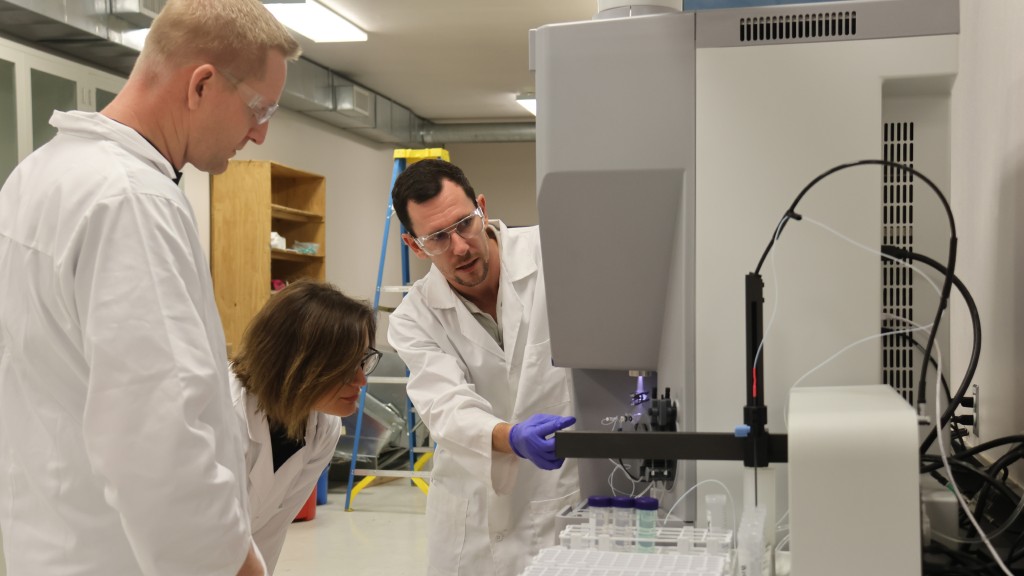

Green Li-ion has launched its first commercial-scale installation to produce sustainable, battery-grade materials in North America. The plant, located within an existing recycling facility, will produce battery-grade cathode and anode materials from concentrated components of spent batteries using Green Li-ion's multi-cathode-producing green-hydro rejuvenation technology.

The current recycling process for spent lithium-ion batteries in North America includes sorting batteries before shredding, which are then processed into "black mass" and further into sulphates. The material is then exported overseas for further processing. Green Li-ion's technology utilizes a hydrometallurgical approach that closes the recycling loop by directly converting recycling scrap into battery-grade precursor cathode active material (pCAM) without being exported for further processing. In contrast to legacy processes, Green Li-ion's process reduces production time, yielding pCAM in around 12 hours. Green Li-ion says its process produces up to 90 percent fewer GHG emissions than virgin materials processing. The Green Li-ion installation is capable of processing unsorted black mass of different Li-ion battery chemistries into pCAM at commercial scale. The Atoka plant and all other Green Li-ion installations are customizable, capable of producing materials meeting the specifications battery cell producers require.

"Green Li-ion's installation closes a critical gap in the North American battery recycling supply chain," said Leon Farrant, CEO and co-founder of Green Li-ion. "Electrification will require manufacturers to exert greater control over their critical mineral supplies. We aim to show American companies the benefits of a customizable and fully vertically integrated battery recycling solution when operating as part of an existing manufacturing process."

Green Li-ion offers flexible options for manufacturers and recyclers to utilize its technology either through a licensing agreement that allows the plant to be installed in their facilities or through a tolling agreement where they can send their black mass to Green Li-ion-owned plants for processing directly into battery materials. This flexibility allows recyclers to integrate Green Li-ion's technology into their production process. Alternatively, recyclers can adjust their supply chains and associated costs via tolling. In addition, the modular nature of Green Li-ion systems allows for deployment and setup that enables operations to begin in a few months instead of building dedicated infrastructure over several years.

By on-shoring black mass and battery waste processing with cathode and anode material production, battery manufacturers and recyclers can significantly reduce the cost and CO2 emissions impacts of their operations and supply chains. Provisions in the Inflation Reduction Act (IRA) have made U.S. battery recycling even more attractive, thanks to tax credits for companies that manufacture batteries in the U.S. and credits for companies using recycled battery materials.

The Green Li-ion plant in Atoka is expected to create two metric tons of pCAM at battery grade, or the equivalent of 72,000 smartphone batteries per day, with plans to quadruple this capacity within the coming year.