Reworld converts industrial waste into low-carbon fuels for cement and lime kilns

The company’s Birmingham MPF uses eFACTOR3 equipment to produce solid alternative engineered fuel, replacing fossil fuels

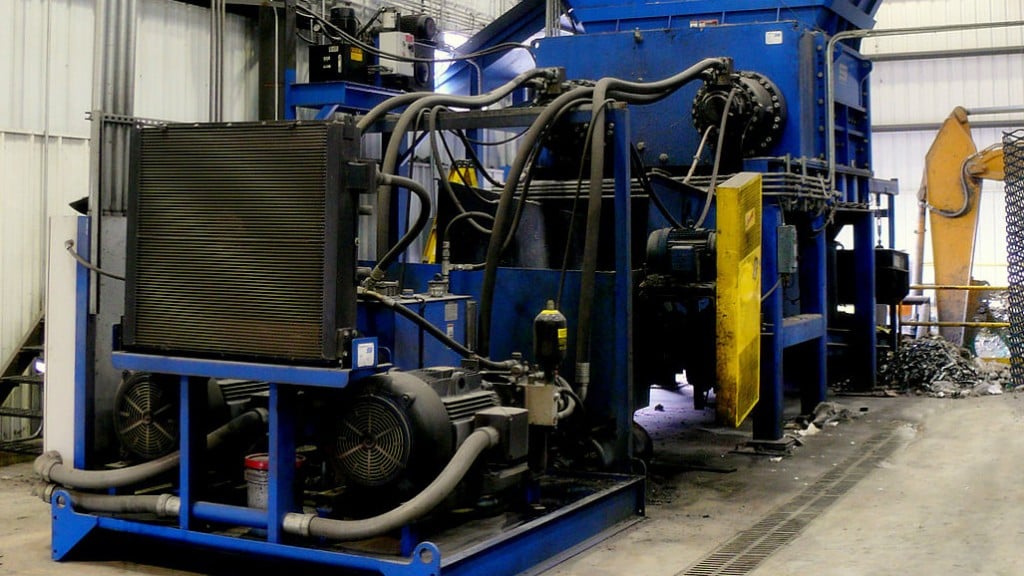

Reworld's Birmingham material processing facility (MPF) is designed to drive sustainability through recycling. One partner that has been instrumental in enhancing the facility's operations is eFACTOR3, a company which offers a large variety of shredding, cleaning, granulating and extrusion equipment along with conveying and separation equipment, systems integration, and installation.

Opened in May 2022, the Birmingham MPF is a facility best known for processing waste into solid alternative engineered fuel (AEF), which displaces the use of fossil fuels in various industrial processes.

This output is sent to nearby cement and lime kilns. The facility is equipped to process up to 100,000 tons of AEF annually, converting commercial industrial waste from sectors such as automotive manufacturing, plastics, food and beverage, and consumer packaged goods into customized, low-carbon fuels that power the cement and lime kilns and significantly reduce their carbon footprints in the process.

Technology driving efficiency and sustainability

eFACTOR3 technology plays an important role in zero waste-to-landfill solutions by handling complex materials that other systems cannot. M&J shredders, Westeria conveyors, and Steinert magnets are engineered to extract maximum value from every load. This process transforms waste into AEF that is tailored to meet the specific needs of cement and lime kilns — producing a more efficient burn with lower emissions.

"The equipment eFACTOR3 provides is versatile but also robust in its ability to handle the more complex materials that are too bulky or tough for other systems. The equipment is on the cutting edge of recycling technology with industry leaders," says Ben Haney, facility manager at the Birmingham MPF.

The eFACTOR3 equipment is boosting recovery and uptime efficiencies, helping the facility meet production targets. At the Birmingham MPF, this advanced technology has allowed the company to consistently produce over 50,000 tons of AEF annually, and Reworld anticipates nearly doubling that number as the intake of waste materials is increased.

A partnership built on shared sustainability goals

Both eFACTOR3 and Reworld share a commitment to sustainability, with both companies focused on lowering carbon emissions and creating long-term environmental benefits through the processing of waste. The partnership aims to demonstrate that advanced waste processing can be both economically viable and environmentally responsible.

Company info

15050 Choate Circle, Suite E

Charlotte, NC

US, 28273

Website:

efactor3.com

Phone number:

704-944-3232