Molg secures $5.5 million funding for robotic microfactories that disassemble electronics

Electronics waste in landfills contains critical minerals and precious metals that are left unrecovered and are a historically overlooked source of valuable resources

Today, tens of millions of tons of electronic devices are discarded or become obsolete each year. In 2022, only 22.3 percent of e-waste was recycled, according to data from the UN Global E-waste Monitor, resulting in the vast majority of electronics being sent to landfill, where they release greenhouse gasses and chemical substances into the environment.

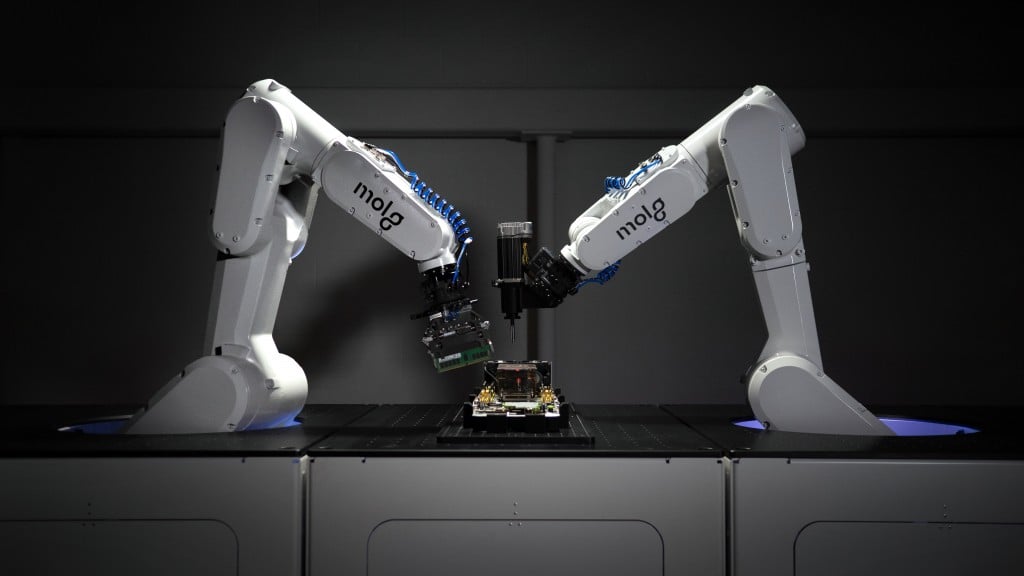

Molg Inc. has developed a comprehensive circular manufacturing process for electronics using robotics and collaboration with manufacturers. Its robotic microfactories can autonomously disassemble complex electronic products to recover valuable components for reuse, remanufacturing, or recycling. The company partners with leading manufacturers to design electronics with circularity in mind — ensuring one product's end is another's new beginning.

"After a decade in consumer electronics manufacturing, we founded Molg because we saw firsthand how current design, production, and recovery processes — or the absence thereof — contribute to the massive problem of e-waste," says Molg co-founder and CEO Rob Lawson-Shanks. "Achieving true circularity requires a fundamental shift in the underlying systems that support demanufacturing. It starts with better design and is enabled by dynamic automation."

On October 9th, Molg disclosed that it has secured $5.5 million in seed funding to scale the company's circular manufacturing processes for electronics and electrical components. Closed Loop Partners' Ventures Group led the round, with participation from Amazon Climate Pledge Fund, ABB Robotics & Automation Ventures, Overture, Elemental Impact and Techstars. Molg plans to use funding to scale production capacity and meet growing customer demand for circularity and automation.

"This funding allows us to accelerate our work at both ends of a product's life, designing for circularity from the start and recovering valuable devices, components, and materials through automated disassembly," says Lawson-Shanks.

Venture capital sees opportunity in the electronics circular economy

"We invested in Molg because they are rethinking how critical materials can be recovered from electronics, addressing a historically overlooked source of valuable resources. Their process maximizes the value of recovered materials and allows for local recovery where materials are most needed -- important parts of advancing the circular economy," says Aly Bryan, investor on the ventures group team of Closed Loop Partners, a firm focused on building the circular economy. "They are helping to unlock a scalable solution that not only reduces environmental impact but also strengthens supply chains by recovering materials domestically."

Over $62 billion worth of critical minerals and precious metals are left unrecovered within electronics waste, missing the opportunity for reuse and remanufacturing for clean energy supply chains. As these materials grow increasingly scarce, expensive, and geopolitically sensitive, more solutions are needed to ensure they are kept in circulation.

Demand for critical minerals is rising due to AI and expansion of data centres

"The AI boom and rapid expansion of data centres is coinciding with an energy transition that demands an immense supply of critical minerals. Molg helps hyperscalers and electronics manufacturers tap into the supply of retired servers and other e-waste that still contain immense material value," says Overture Climate VC managing partner, Shomik Dutta. "Molg's robotic solution not only moves the industry towards circularity; it presents a supply that is cheaper and more domestically secure."

Molg has its headquarters and manufacturing facility in the heart of the data centre industry in Northern Virginia. Molg has already installed robotic disassembly Microfactories at Sims Lifecycle Services and is rolling out to ITAD facilities of leading hyperscalers. The team also works on circular design with leading companies like HP, Dell, and ABB Robotics & Automation Ventures to redesign products for the automated recovery of valuable components, remanufacturing, and recycling.

"Our investment in Molg will open new possibilities for using industrial robots in the recovery and recycling of data centre equipment," says ABB Robotics managing director of business line industries, Craig McDonnell. "By helping to enable the automated disassembly and responsible disposal of disused electronics, we are excited to be playing our role in transforming the circularity and sustainability of the data centre sector."