Smithsonian celebrates early recycling innovations

Revolutionizing Recycling: The “Prolerizer” collection added to the Smithsonian’s National Museum of American History

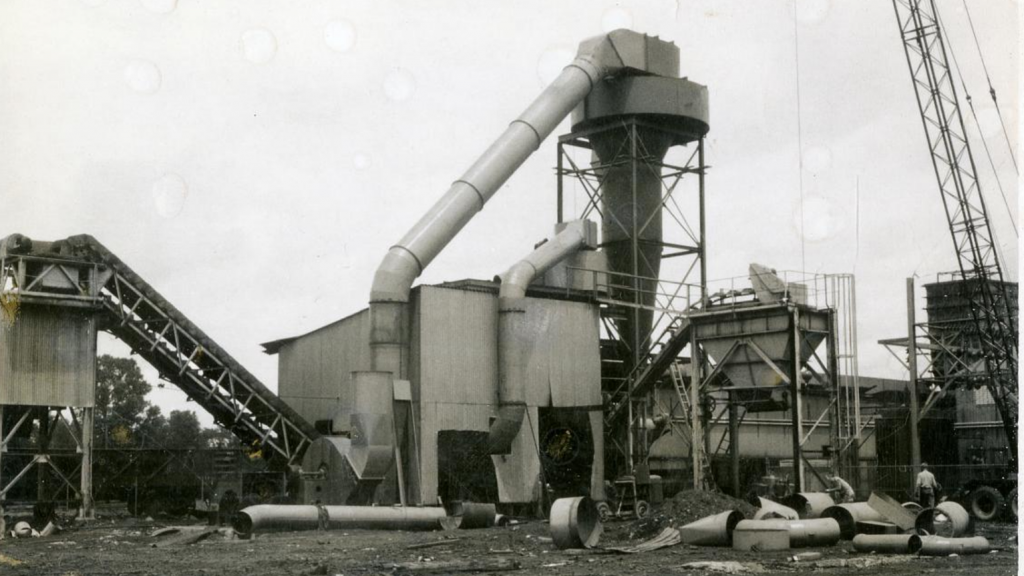

Ben Proler's "prolerizer" was a significant evolution in the ability of companies to recycle materials from large, durable consumer products. Patented in 1961, the machine could shred an automobile or other large durable consumer products in minutes, transforming recycling around the world.

Now the machine will be a permanent part of the Smithsonian Institute, thanks to a donation from Joshua Jones, regional manager of Advantage Metals Recycling. The collection is called Revolutionizing Recycling: The "Prolerizer", and it features a section from the original prolerizer, which is a significant piece of industrial history.

Prior to the prolerizer, automobile recycling was a labour-intensive process involving handheld torch cutters and alligator shears, with derelict cars becoming a widespread problem for American towns and cities.

The Prolers found a way to grind up cars, extract clean steel, and send it back to steel mills to create new products. The primary invention consisted of a rotor with many hammers, powered by a large engine, that could shred entire vehicles into small fist-sized pieces that could be separated into ferrous and non-ferrous materials, providing steel mills with a superior quality of scrap to recycle into steel.

Ben Proler started the family business in the 1920s, and with the help of his sons Izzy, Sammy, Hymie, and Jackie, transformed a local scrap dealership in Houston into Proler Steel, a publicly held global company. Advantage Metals Recycling decommissioned its 1961 Prolerizer in the summer of 2024, donating a representative part of the machine and early archival materials to the museum.

This collection is open to researchers. The Recycled Materials Association, AMR, the Proler family, museum curators, and archivists plan to continue to build this collection in the next year.

![[VIDEO] Glacier and the evolution of AI and data-driven technology in recycling [VIDEO] Glacier and the evolution of AI and data-driven technology in recycling](https://media.baumpub.com/files/slides/locale_image/full/0243/60710_en_06c2a_62723_bq4a7681copy.jpg)