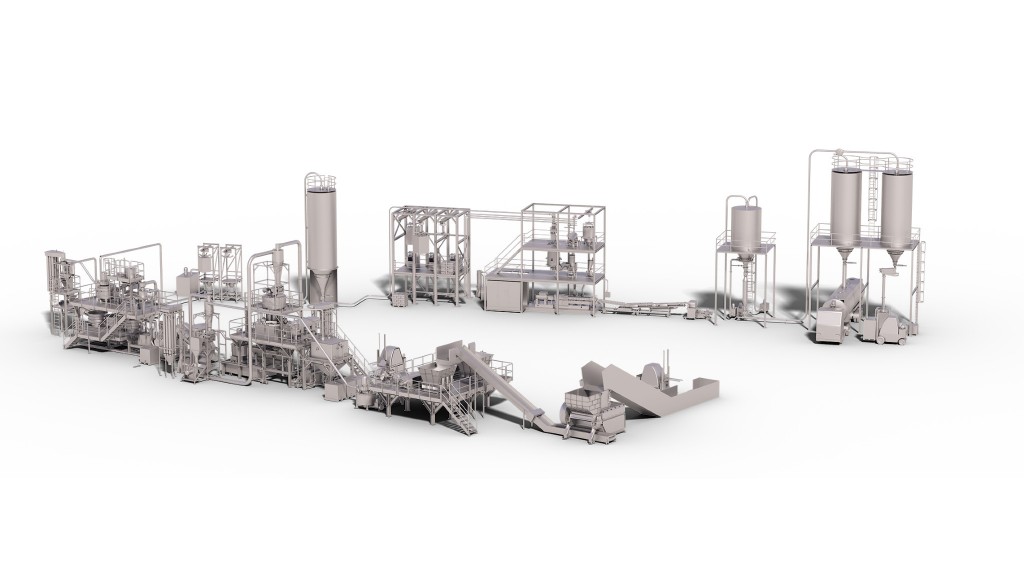

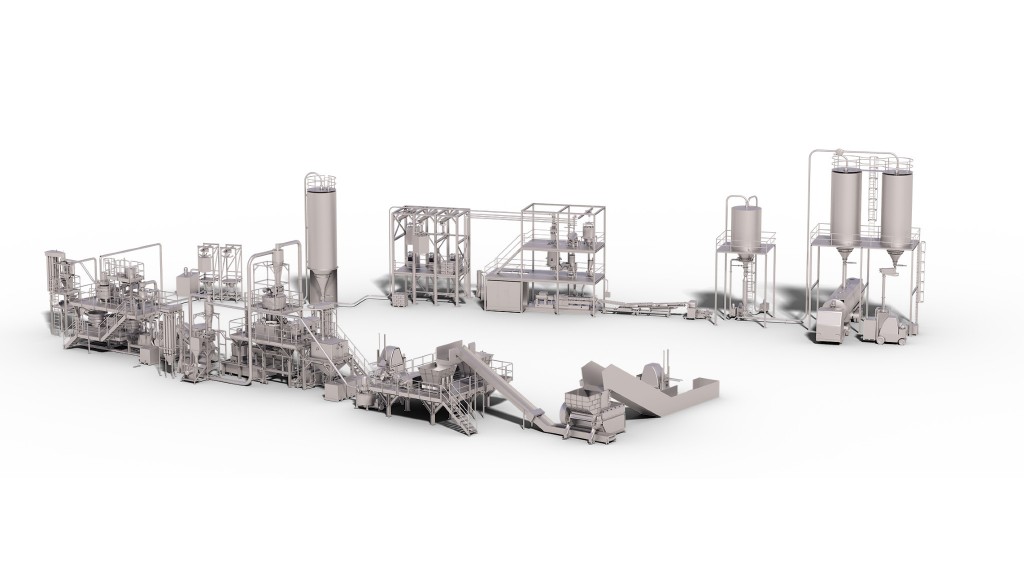

For Magpet Polymer Pvt Ltd, an Indian preform and plastic packaging manufacturer, Coperion and Herbold Meckesheim are collaborating to build a plant for bottle-to-bottle recycling from a single source. In addition to the mechanical processing of used PET bottles, the recycling system encompasses all process steps leading up to extrusion with a ZSK twin screw extruder, including pelletizing and an SSP (solid state polycondensation) reactor.

This PET bottle recycling system is designed for a throughput of 5,500 kg/h. It will deliver PET recyclate that is approved by the European Food Safety Administration (EFSA) and the U.S. Food and Drug Administration (FDA) for direct contact with food. Moreover, Coperion and Herbold Meckesheim say that the PET pellets manufactured on this bottle-to-bottle line are brand-owner-approved.

"Magpet has always pursued the goal to be a first mover when it comes to embracing new technology," said Devendra Surana, managing director of Magpet, a part of Magnum Group. "This PET recycling unit is a big step in that direction. And it goes hand in hand with our efforts to take over business responsibly for a bigger eco purpose."

Magpet awarded the contract for the entire system to Coperion and Herbold Meckesheim as they have coordinated their technologies and realized efficient plastic recycling solutions that reliably deliver high PET recyclate quality.

Coperion's and Herbold Meckesheim's bottle-to-bottle plants enable recyclates to be processed together, even if they exhibit different IV (intrinsic viscosity) values or fluctuating bulk densities. What is more, the Coperion-Herbold solution saves on operating costs, logistics costs, and energy consumption in comparison to conventional PET recycling processes.

The bottle-to-bottle recycling system first processes the PET bottles into flakes. For this purpose, Herbold uses granulators with forced feeding and washing system technologies that efficiently and gently process the PET to minimize material loss due to fines formation.

This preprocessing is followed by conveying and feeding into the ZSK recycling twin screw extruder. There, the PET regrind is gently melted, dispersed, and then processed into a homogeneous mass. The ZSK's twin screw technology efficiently transfers the energy into the melt. Thanks to the twin screw extruder's 18 Nm/cm³ torque, the PET's residence time in the extruder is short. Processing takes place at low temperatures and polymer chain degradation is minimal. Volatile components such as monomers, oligomers, and water are removed from the melt and purged.

Following discharge from the ZSK recycling extruder, the still-warm material stream is transferred via a gear pump to an underwater granulator and an SSP reactor, where it is then condensed and decontaminated.

"In the bottle-to-bottle recycling plant for Magpet, we have united the advantages of Coperion and Herbold Meckesheim technologies. All process steps, from mechanical pretreatment to producing finished recyclate, are optimally coordinated to produce PET of high quality – and with maximum energy efficiency," says Jochen Schofer, head of sales recycling at Coperion.