ZenRobotics and Terex Recycling Systems will establish a fully robotized, efficient, and cost-effective material recovery facility (MRF) at Bjorstaddalen's plant in Norway. Bjorstaddalen is a prominent Norwegian waste management company. The new facility will enable decentralized and profitable household waste recycling, integrating AI-powered robotics with modular waste sorting solutions.

Bjorstaddalen wants to reduce incineration and landfilling by harnessing AI-powered robots and modular recycling equipment.

"Our current autonomous material recovery facility is already an industry pioneer," says Sindre Hauen, managing director of Bjorstaddalen, "efficiently handling construction, demolition, and residual waste. Now, we embark on a transformative journey to establish a decentralized material recovery facility that is tailored for municipal household waste and promises cost-effectiveness. The Fast Picker robots excel at sorting diverse materials, including various plastics, paper, and cardboard, while the Heavy Picker robots efficiently manage bulky items weighing up to 40 kilograms. Remarkably, this technology enables precise sorting to dozens of material categories, including the effective handling of black plastics. The meticulously designed MRF is poised to commence construction in just three weeks, with full operational readiness targeted for April next year."

The forthcoming Bjorstaddalen plant is a prime example of the synergy that exists between AI robots and other modular solutions.

"The modularity of our solutions ensures swift installation without compromising performance or reliability, offering end-users adaptability to evolving business and market demands," adds Kenny Hull, product and commercial manager at Terex Recycling Systems. "Combined with AI robots, this positions us as a comprehensive destination for state-of-the-art recycling systems."

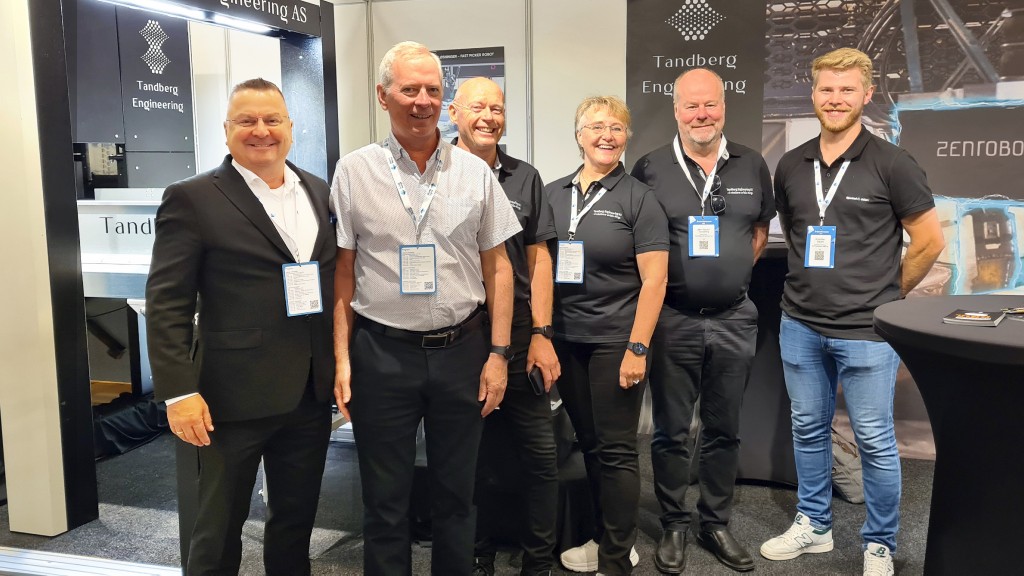

The agreement to build the MRF was signed between ZenRobotics and Terex Recycling Systems and Bjorstaddalen and Tandberg Engineering.