At K 2022, Lindner will present a range of products and highlight a new system to directly process post-consumer rigid plastics in an injection moulding process.

The circular economy and the growing importance of plastic recycling under the umbrella of climate protection are key topics at K 2022. Undoubtedly, there has been an upswing in plastics recycling for several years. The challenges facing the industry, however, continue to be multifaceted and complex: demand for recyclate quality is increasing as is the call for higher throughputs with minimal energy consumption and maintenance. The driving force behind this is clear: Plastic needs to be retained in the cycle for as long as possible and the aim is also to increase the use of recycled plastic material in the food sector. The key to recycling success lies in the coordination of the upstream processes of shredding, washing, and sorting. Lindner offers solutions to help with these steps while processing rigid plastics, film, and PET.

Shredding waste plastic is right at the start of the plastics recycling process – an area in which Lindner can apply its experience in the processing of domestic, commercial, and industrial waste to obtain standard throughputs of 40 t/h and more. At K 2022, Lindner will be presenting the upgraded Jupiter BW series. The upgraded Jupiter BW series is focused on optimizing the handling of plastic films for the downstream NIR sorting process. In addition to a constant volume flow and homogeneous larger particles, this also includes optimizing the particle size for NIR sorting.

"With a particle size of DIN A4 to A3, we have been able to improve the performance of the NIR systems with our customer," says Stefan Scheiflinger Ehrenwerth, head of product management at Lindner. "Every shredding process generates a certain proportion of fines along with the targeted ideal particle size. With the new, resource-efficient Jupiter BW set up, we have managed to reduce the proportion of fines generated by 50 percent, which manufacturers of NIR sorting equipment have confirmed."

As a result, the cutting system of the Jupiter BW series is able to significantly increase the added value along the chain.

A focus on quality and efficiency

Besides shredding and sorting, the washing process is also a key quality criterion for producing high-quality regranulate.

"We are only too familiar with the problem. But we also have the right solutions," says Harald Hoffmann, managing director of Lindner Washtech, Lindner's subsidiary specializing in plastics recycling. "Our patented Rafter pre-wash has been tailored to the new requirements. By using a larger rotor, we can lengthen the dwell times, which obviously has a positive effect on the depth of cleaning. We have also been able to sustainably improve the throughput rate, 3 t/h for films and 5 t/h for rigid plastics – and we will be showcasing this product innovation at the K trade fair for the first time."

Lindner will also be highlighting a thermal dryer at K 2022.

"At K, we will also be introducing EcoDry, our new thermal dryer. Clever use of heat exchangers and a sustainable insulation of the material-conveying components means this dryer achieves energy savings of up to 30 percent. And the high degree of drying also ensures the flakes are better prepared for subsequent processes."

Demonstrations of Lindner's new equipment

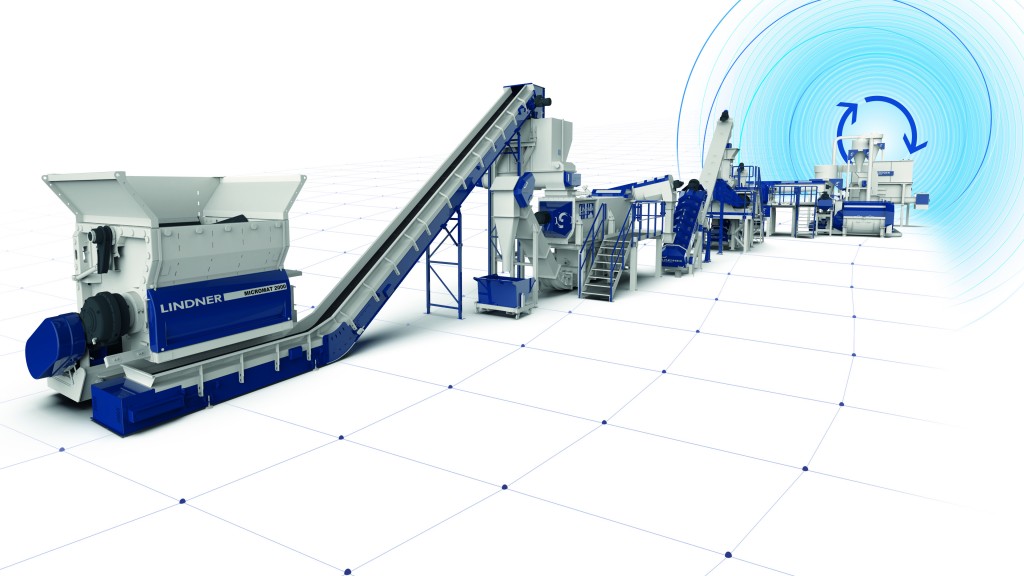

Lindner is in the outside area of K 2022, and this year the company will be exhibiting as part of the VDMA Circular Economy Forum. Showcasing its products together with several other companies along the entire value chain. Lindner will be presenting a shredding, washing, and drying unit with integrated water treatment and will be recycling plastics live several times a day.

Shredding is performed by a model from the new Micromat HP series – a machine equipped with new functions that offer high throughput performance and ease of maintenance. The bolted knife system and its enhanced drive make the Micromat HP series an energy-efficient machine in plastics recycling, and can be used to shred films and rigid plastics. Visitors will be able to see how rigid plastics pass through Lindner's recycling machine, and – without prior extrusion – enter into an injection moulding process.