The steel recycling industry is one of the oldest and most important members of the recycling community. With electric arc furnaces in the value chain, ferrous scrap purity continues to pressure resource efficiency. It is the use of steel scrap in new steel production, not iron ore and coking coal, that preserves natural resources. By recycling steel, scarce raw materials are preserved, energy is saved, and the environment is spared considerable carbon dioxide emissions along with other waste products. STEINERT sorting equipment aids in the production of pure, clean steel. It is key to unlock the value of ferrous scrap streams and avoid potential steel mill penalties and to refine the pathway to a circular economy.

For every ton of steel scrap that is used instead of primary raw materials in steel production, 1.67 t of ore and 0.5 t of energy resources (coal, coke, heavy fuel) do not need to be mined, transported long distances, and consumed. For these reasons, the phrase "Green Steel" has been coined and entered everyday use.

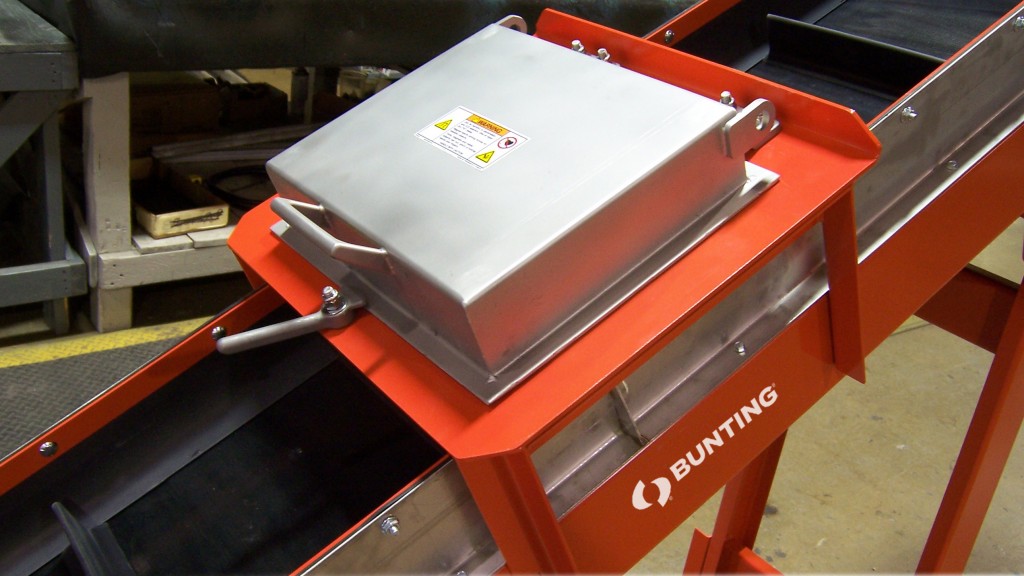

But producing recycled raw materials for the manufacturing industry first requires the materials to be sorted. Steinert's new Solution Guide will show how to best clean steel scrap.

Typical applications and demand:

- Recovery & purification of ferrous scrap from shredder scrap

- Cleaning of heavy melting scrap HMS (E1/3) from shear scrap processing

- Recovery & upgrade of ferrous products from e-scrap or lighter mixed scrap materials

Find STEINERT's steel recycling solutions guide here.