Ascend Elements will recycle SK Battery America's lithium-ion cell and module manufacturing waste

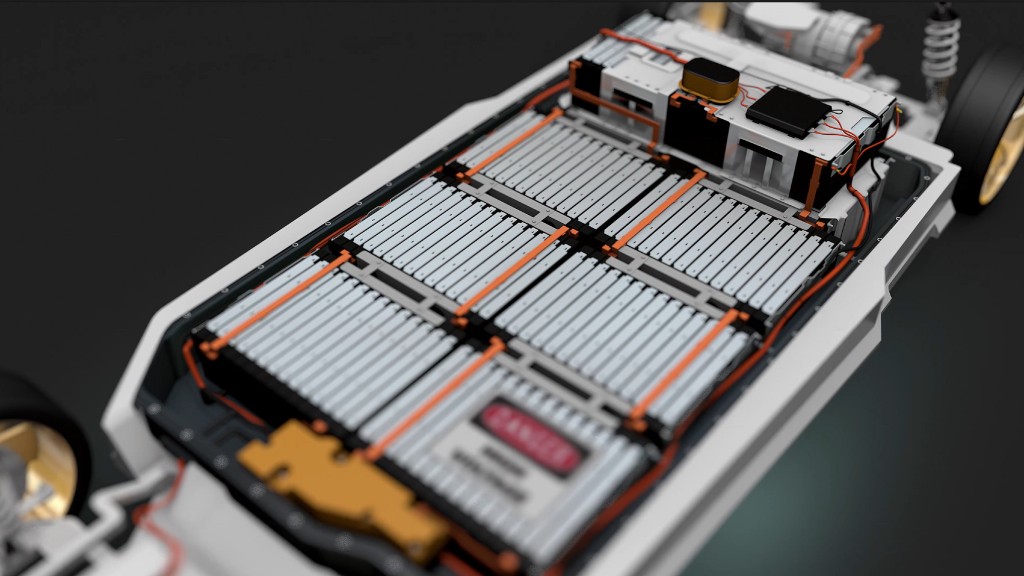

Ascend Elements has been selected by SK Battery America (SKBA) to recycle both cell and module lithium-ion battery manufacturing scrap from the company's manufacturing facility in Commerce, Georgia. The scrap material will be recycled at Ascend Elements' 154,000 square-foot battery recycling facility in Covington, Georgia, which can recover 98 percent of battery materials and return critical battery elements to the battery supply chain.

"People often think lithium-ion battery recycling is just for end-of-life batteries, but waste from the battery cell manufacturing process is the biggest segment of the battery recycling market right now," said Michael O'Kronley, CEO of Ascend Elements. "SKBA is embracing sustainability and reducing its impact on the environment by recycling every bit of scrap battery material it produces. We are incredibly proud to have our new recycling base in Covington, G.A. and we look forward to helping SKBA conserve valuable material and keep battery production costs down. We are committed to continuing our work with SKBA and eventually returning the battery materials we recover to their supply chain. Lithium-ion battery recycling and materials recovery needs to become standard operating practice across the industry to minimize our dependence on mining, protect the environment and conserve valuable battery metals."

"Our vision is to create a circular supply chain for electric vehicle batteries from raw materials to recycling in the United States," said Alex Yarbrough, an environmental engineer at SK Battery America. "We will move forward with Ascend Elements to improve the overall carbon-reduction value of EVs."

Ascend Elements raised $90M in 2021 to expand its battery recycling and cathode manufacturing operations and recently shared plans to open the Covington, Georgia, recycling facility, which will have a 30,000 metric tons per year capacity when fully operational late 2022. The company will continue expanding its commercial recycling and battery materials manufacturing operations in 2022 and 2023.