Construction and demolition waste is generally not suitable for reuse or high-grade recycling, often resulting in mixed construction waste being used as low-grade material or even disposed of entirely.

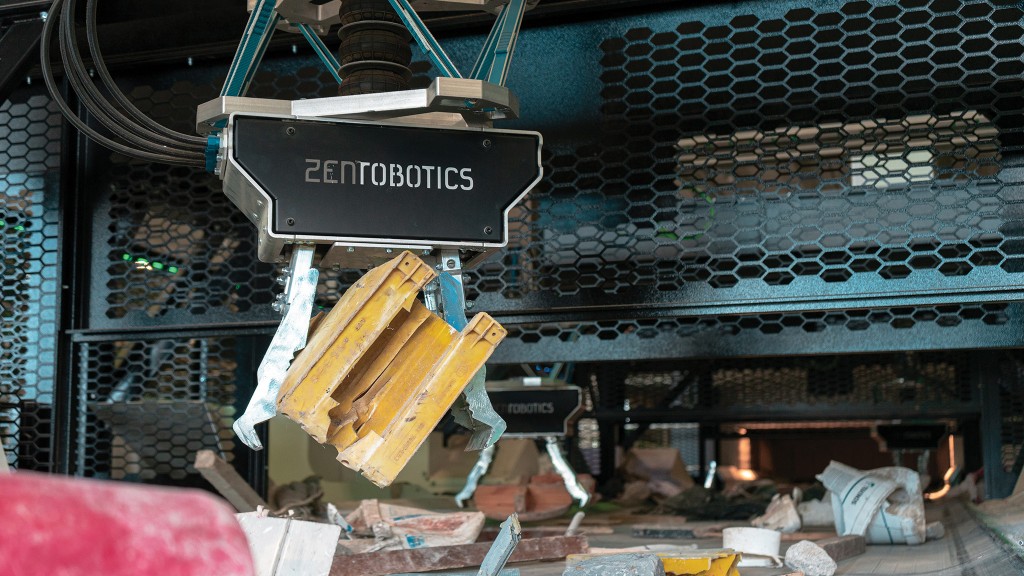

ZenRobotics, a global specialist in smart robotic recycling, is tackling this issue by using its AI-based sorting robots to turn waste into clean raw materials. Companies looking to increase the quality of their waste have incorporated ZenRobotics' sorting robots into their day-to-day operations to help improve efficiency, increase purity rates, and reduce costs.

One such company is the Swiss family-owned Eberhard Group, one of ZenRobotics' long-time partners. Eberhard Group's newest plant will recover high-purity materials from C&D waste using advanced AI and robot technologies to convert clean materials into new, high-quality, and fully circular raw material for buildings.

"After water, concrete is the most used resource of the world and mixed demolition waste is one of the biggest waste streams landfilled," said Patric van der Haegen, division head development of the Eberhard Group. "We simultaneously dig enormous holes into the planet while piling up huge mountains on the other side. New sustainable alternatives are needed. Our new EbiMIK plant sorts mixed demolition waste in all its components. This boosts the circular economy because each valuable material can be reused individually. Robots with artificial intelligence play an important role in this revolutionary new facility."

The Eberhard Group believes that the circular raw material will lead to significant emission reductions. The production of cement, a key component of concrete, involves combustion processes that release carbon dioxide into the atmosphere, contributing to global climate change. According to the Eberhard Group, their new zirkulit concrete will save 10 kilograms of carbon emissions per cubic metre while providing the same mechanical and chemical qualities as conventional concrete. The new zirkulit concrete is also optimized to use almost seven percent less cement than conventional concrete.

Smart robots do the hard and dirty work

To ensure that all high-purity secondary materials are captured from mixed C&D streams, the Eberhard Group's new plant uses intelligent robots as the main sorting system. This includes two parallel sorting lines with multiple high-capacity robots on each line. The robots pick up to 12,000 items per hour, separating mineral materials and impurities from the stream.

ZenRobotics' AI-based robots can sort a wide range of materials from C&D as well as industrial and household waste. As clean, recyclable fractions like wood, plastics, metals, and stone aggregates are captured from waste streams, they can be reused as secondary raw material and replace the need for virgin raw materials or fossil fuels.

"We have been working with the Eberhard Group since 2015 and are impressed by their pioneering commitment to find new, circular solutions for construction materials," said Jarmo Ruohonen, CEO of ZenRobotics. "Indeed, Eberhard was one of the first operators to see the possibilities of AI-based sorting in improving the efficiency and profitability of waste management. We are proud to be part of this exceptional facility that applies our smart waste management solutions while helping to reduce carbon dioxide emissions significantly."

Denmark's first autonomous robot sorting plant for C&D waste

Another recycling specialist working to help improve efficiency, increase purity rates, and reduce costs by using ZenRobotics' sorting robots is Danish environmental services company Solum A/S. The company is set to open its first fully autonomous robotic sorting plant in the summer of 2022, which will utilize AI and robotic technologies by ZenRobotics to sort up to 25,000 tons of mixed waste per year, including combustible waste, bulky waste, metal, wood, and plastic. The robot sorting plant will raise the recycling percentage and quality of waste at Solum A/S, improving recycling efficiency, work safety, and contributing to the circular economy.

Solum's new robot waste sorting plant consists of multiple robot arms that lift objects up to 30 kilograms and handle up to 4,000 picks per hour, 24 hours a day. By comparison, a human can handle approximately 700 picks per hour. The sorting plant also eliminates occupational health risks associated with manual sorting, increases the degree of purity by up to 98 percent, and reduces the associated costs.

Fully autonomous sorting system runs 24/7

Solum's new facility is a fully autonomous standalone robotic sorting station that is independent from other operations and replaces manual processes in waste sorting. The material first goes through a simple screening step where fines and foils are sorted out. The material is then loaded into a feeding bunker where the material flows evenly and autonomously to the robots through a loader. The AI-powered sorting robots work independently and empty the feeding bunker during the day and again during the night when employees on the site go home. In the morning, the employees arrive and fill the feeding bunker, and the process starts all over again.

"We are thrilled to partner with Solum A/S and ReTec to bring the first AI-powered robot sorting plant for C&D and C&I waste to Denmark, placing more robots on the world map," said Ruohonen. "The fully independent and automated waste sorting plant creates a safer and more efficient recycling environment, lowering operating costs and recovering more valuable, high-quality fractions. Modern waste sorting infrastructure is essential to transition to a circular economy and meet the increasing demand for high-quality recycled materials. Frontrunning operators like Solum are leading the way."