Understanding flexible packaging for recycling

With the current global focus on the sustainability of plastics, end-of-life management of flexible packaging has become a priority

Flexible packaging has seen tremendous growth globally, with an annual growth rate of 3.8 percent within North America alone. It can be found in a vast array of shapes and sizes containing a wide range of products such as coffee, laundry detergent, baby food, cat litter, single-serve juices, motor oil, toothpaste and more.

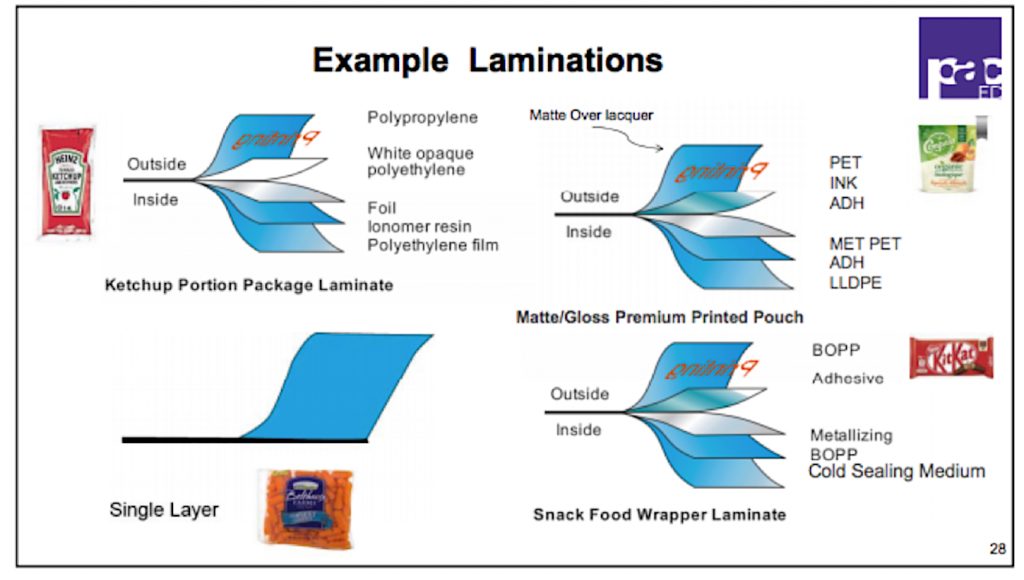

Packages can be made with a single layer, a mono-material laminate (i.e. multiple layers from the same polymer) or the more complicated, multi-material laminate (made from multiple layers from different polymers). Flexible packaging can also include papers and metals as key components, closures using zips, spouts or reseal adhesives, and various additives. While these packaging designs and formulations offer specialized benefits, recovery rates are low or non-existent.

End-of-life management of flexible packaging

With the current global focus on the sustainability of plastics, end-of-life management of flexible packaging has become a priority. Landfill/disposal is the default end-of-life option, with some life cycle assessment studies even suggesting that flexible packaging, if disposed properly, is still a better environmental packaging choice compared to other more recyclable materials.

Other options include thermal (e.g., energy-from-waste) and chemical treatment. Alternatively, reduction based approaches aim to lower (e.g., light weighting) or eliminate material needs, and reuse approaches replace flexible packaging with more durable solutions.

If disposal is not the preferred option, more economically viable and sustainable designs, along with an understanding of the basic polymer properties and construction processes of a flexible package, are required in order to identify the best end-of-life value solution.

Breaking down flexible packaging

Important mechanical properties of a flexible package include the following:

• Mechanical (e.g. tensile strength or tear resistance)

• Barrier (e.g. oxygen or water)

• Sealability (e.g. heat-sealing)

• Aesthetic (e.g. printing)

The ubiquitous potato chip bag offers a good example of what's involved in a particular flexible packaging format. Manufactured with extrusion lamination, it typically uses polypropylene as a moisture and odour barrier, low-density polyethylene (LDPE) for strength and grease resistance, and a thermoplastic resin for puncture resistance and heat-sealing.

The illustration above gives a hint of the diverse laminate combinations found in the marketplace. Layers tend to offer functional benefits. For example, metallized polyester films are an excellent barrier to moisture and oxygen. Other layers are employed purely to improve aesthetics, such as an extra layer to allow reverse printing, or metallic foil as a base for the eye-catching foil stamping seen on products like chocolate and coffee. Additionally, a myriad of additives offer specialized performance factors (e.g. anti-static, anti-slip, anti-fogging, UV barriers and optical brighteners.)

However, some additives like optical brighteners cannot be removed in the recycling process and can create an unacceptable fluorescence for next uses of the recycled polymer. As noted by the Association of Plastic Recyclers (APR), it is difficult to identify materials with negative effects like this until late in the recycling process, by which time significant cost has been added into a material of low value due to the additive. Furthermore, a recent report notes that certain additives also affect plastic density, leading to losses with certain sortation processes, such as sink-float systems.

How materials affect recycling potential

The growing sophistication of multiple polymers, additives and closures offers many benefits, but presents a significant challenge for recyclers to find economically viable ways to collect, sort, recycle and market their materials.

The following is a sample of research and innovative initiatives that, in various ways, contribute to a deeper understanding of viable recycling of flexible packaging:

• The U.K.'s REFLEX project studied the material composition of the post-consumer flexible packaging waste stream, and found 80 percent to be polyethylene (PE) or polypropylene (PP). REFLEX tested PE and PP - laminated with PET, EVOH and aluminum foil - to evaluate which materials are best used in flexible packaging from a recyclability viewpoint. They found PE/PP laminates produced well-mixed recyclates, with properties suitable for certain injection molding applications. They noted the potential for PE/PP to be reprocessed together, which "would simplify the recycling process for flexible packaging considerably, leading to greater yields and allow brand owners and packaging designers to use PE/PP laminates that are suitable for mechanical recycling."

• In Canada, Recycle BC launched a 2018 research pilot to collect certain types of flexible packaging and figure out how best to recycle them. Consistent with other studies (e.g., CIF Project #749), the preferred method of collection for this material type was determined to be through waste depots and return-to-retail.

• The flexible packaging challenge has also led to chemical recycling innovation, where a polymer is chemically reduced to its original or other monomic forms for processing into new materials. Citing Green Mantra Technologies, Ontario's 2019 Special Advisor's Recycling and Plastic Waste Report signalled a potential openness by Ontario's Provincial government to broaden its definition of recycling.

• The challenges with multi-material properties have also created the impetus for mono-material innovation. In Ontario, Tempo Plastics is one of several businesses exploring mono-material solutions. Tempo uses DOW's Recycle Ready Technology in their Harmony Pack, which uses only HDPE, achieving similar performance to multi-material flexible package.

For Ontario municipalities looking to improve their waste diversion rates, the amount of flexible packaging found in the waste streams serves as an opportunity to gain an additional one to two percent of diversion.

Flexible plastic recycling pilot projects

Starting this fall, the City of London will undertake a two-year pilot project (CIF #1088) that seeks to improve the diversion of flexible packaging and other difficult-to-recycle plastics using the Hefty EnergyBag program promoted by Dow Chemical Company. Residents will be asked to place targeted materials into the program's trademarked orange bags. Full bags are then to be co-collected with residents' blue box materials for separation at the MRF and delivery to an end market. Learnings from the project are expected to include a better understanding of potential end markets along with the cost and operational implications of collecting and processing the targeted materials.

Flexible packaging projections show significant annual growth for the foreseeable future. This growth brings with it an evolving, complex array of formulations blending polymers, additives and closures. The challenge facing recycling stakeholders is considerable. However, as the above examples highlight, many emerging initiatives are helping to identify sustainable processes to manage this growing stream of packaging.

Dave Faris Yousif is project manager at the Continuous Improvement Fund (CIF), an Ontario-based organization with the mandate to improve the effectiveness of Ontario's municipal blue box programs. Visit CIF's website at www.thecif.ca.

This article was first published by the Continuous Improvement Fund, and as above in the October 2019 edition of Recycling Product News, Volume 27, Number 7.