Nestlé Waters North America signs agreement with Recycled PET supplier CarbonLITE

Expanded U.S. operations to result in new Pennsylvania facility projected to process 2 billion post-consumer bottles yearly

Nestlé Waters North America has signed a significant agreement with recycled PET plastic (rPET) supplier CarbonLITE, and that CarbonLITE will expand its U.S. operations by building a third facility in the Lehigh Valley area of Pennsylvania.

The new contract builds upon Nestlé Waters' existing relationship with CarbonLITE, one of the largest producers of food-grade, post-consumer rPET, and allow the beverage company to further expand use of recycled materials in its packaging. The company currently purchases rPET from CarbonLITE's existing facilities in California and Texas.

"We are pleased that CarbonLITE will be locating a facility in a region important to our manufacturing footprint," says Bill Trackim, Vice President, Head of Supply Chain and Procurement at Nestlé Waters North America. "Being able to purchase rPET in the area helps us better support the regional economy while promoting environmental sustainability through the use of renewable and recyclable materials in our packaging."

CarbonLITE anticipates the facility will be in full production by early 2020, and will have the ability to recycle over 2 billion post-consumer bottles a year. The new 200,000-square-foot processing facility is anticipated to save 60,000 tons of carbon annually by using post-consumer materials and produce 80 million pounds per year of food-grade rPET pellets.

"Nestlé Waters continues to be a leader in their sustainability efforts," says Leon Farahnik, Chairman of CarbonLITE Industries, LLC. "We are proud to have grown with them for the past seven years and proud to expand our relationship in our state of the art facility in Pennsylvania".

Nestlé Waters, which has two bottling facilities in the Lehigh Valley, uses recycled plastic in a number of its brands including Nestlé Pure Life® and Deer Park® which are bottled locally. The company has been increasing the amount of rPET it uses in its packaging since 2011, and in February 2018, Nestlé Waters launched a 700ml Nestlé Pure Life® bottle made of 100 percent rPET. In California, all of the company's single-serve sizes of Arrowhead® Brand Mountain Spring Water and Nestlé® Pure Life® bottles produced in the state are made with 50 percent rPET.

Nestlé Waters' parent company, Nestlé SA, is a signatory of the recently announced New Plastics Economy Global Commitment. An initiative of The Ellen MacArthur Foundation and UN Environment, the "Global Commitment" is an agreement to ensure that 100 percent of plastic packaging can be reused, recycled or composted by 2025.

At the end of October, Nestlé joined forces with other businesses and governments in signing The New Plastics Economy Global Commitment ('Global Commitment') at the Our Ocean Conference in Bali, Indonesia. The Global Commitment aims to rethink the future of plastics by applying the principles of circular economy, in which plastics never become waste, and represents a powerful framework to work collectively on solutions that address the root causes of plastics waste and pollution.

Nestlé CEO Mark Schneider said, "This Global Commitment is a step-change we urgently need in order to move from a linear to a circular economy. We want to act and lead by example. We will do our part to ensure that none of our packaging, including plastics, ends up in the natural environment."

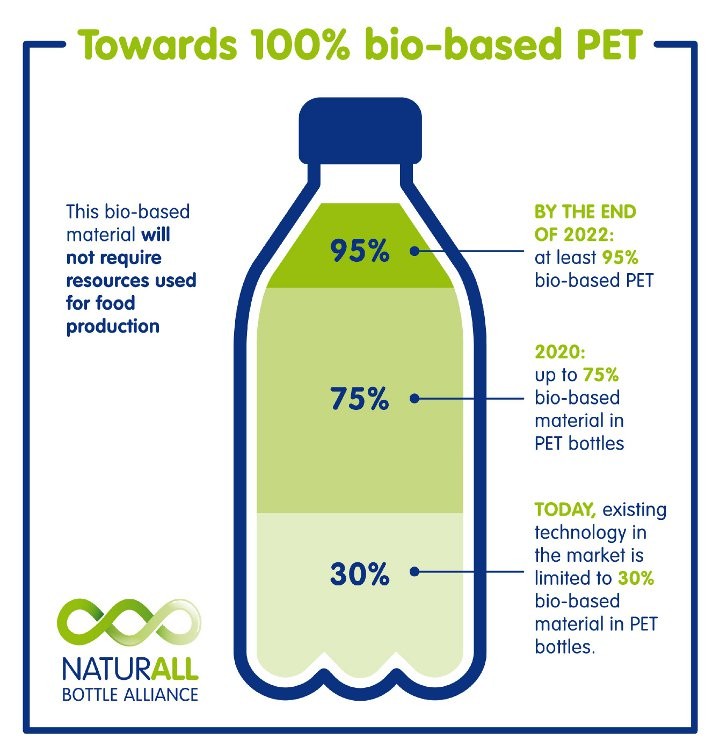

Nestlé has also recently embarked on several exciting research and development projects. One of them is the NaturAll Bottle Alliance, which aims to develop 100% bio-based PET to be used for its water business.