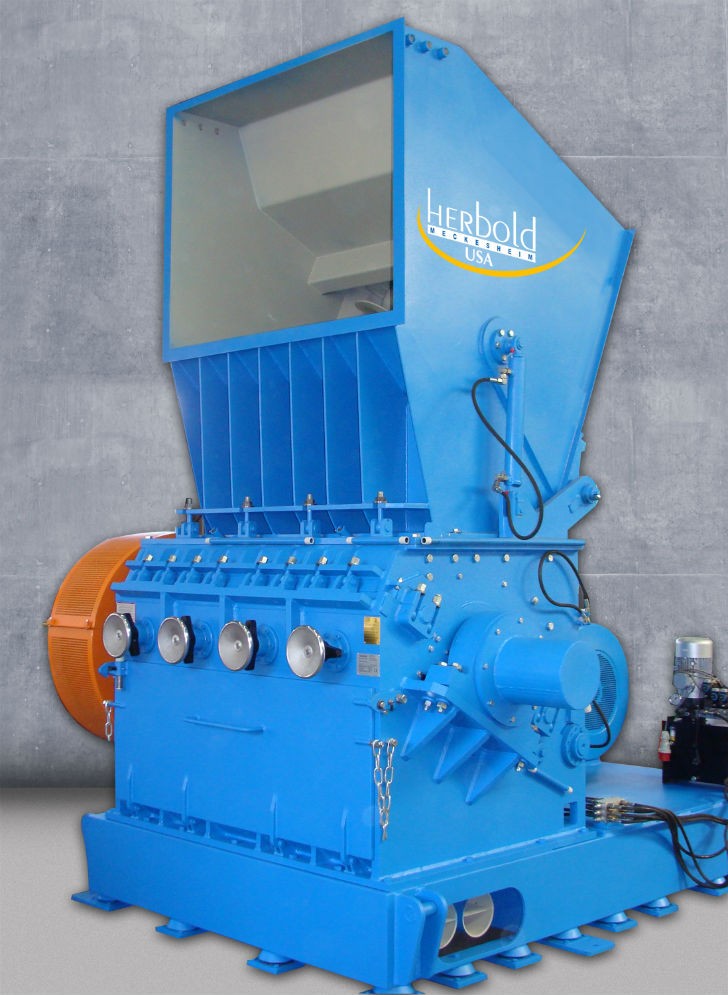

Force fed granulator has oversized rotor for higher throughput

Herbold USA has announced the availability of a new force fed granulator for size reduction of PET bottles. The Model SMS 100/160-9-2 SB3 features a rotor that is 20% larger than current offerings. The additional size and mass of the rotor allows the granulator to operate at higher throughput rates (up to 7 tons per hour).

Material is fed into the destruction chamber via a patented screw fed mechanism that utilizes 3 vertically mounted feeding screws. This feeding method offers several advantages over gravity feeding including consistent, even feed rates, reduced power consumption, no material flyback, quieter operation, less wear on the cutting chamber, and reduced fines and dust.

The unique knife geometry which positions inclined rotor and stator knives at the same, but opposing angles provides a true double cross cutting action.

Herbold Meckesheim USA, a subsidiary of Herbold Meckesheim Germany, designs, manufactures, and installs size-reduction equipment (shredders, granulators, etc.) and wash-line systems for the plastics industry, specializing in the recycling of industrial and post-consumer plastics.