The critical role of AI and robotics in the shift toward urban mining

Technology holds the key to transforming e-waste into a valuable resource

Earlier this year, the European Commission released the Critical Raw Materials Act which outlines proposed regulations to ensure a secure and sustainable supply of critical raw materials (CRM). These materials are essential for the economy, but are largely reliant on imports from foreign countries. This act reflects a clear direction in developed countries toward urban mining – the extraction of valuable metals and resources directly from electronic waste through recycling processes – as a substitute for traditional mining.

The challenges and risks of urban mining

While this transition is both inevitable and desirable, it comes with challenges and risks that must not be underestimated. Optimizing recycling processes and recovering reusable materials in an economically sustainable manner is crucial, as is the implementation of new legislation. However, there is also a risk of social issues arising or worsening.

For instance, the Agbogbloshie landfill in Accra, Ghana, which theoretically ceased operations in 2021, employed impoverished individuals – often children – who worked amidst mountains of electronic waste that was shipped to Ghana from more developed nations under the false label of "second-hand devices." This had devastating consequences for their safety and health.

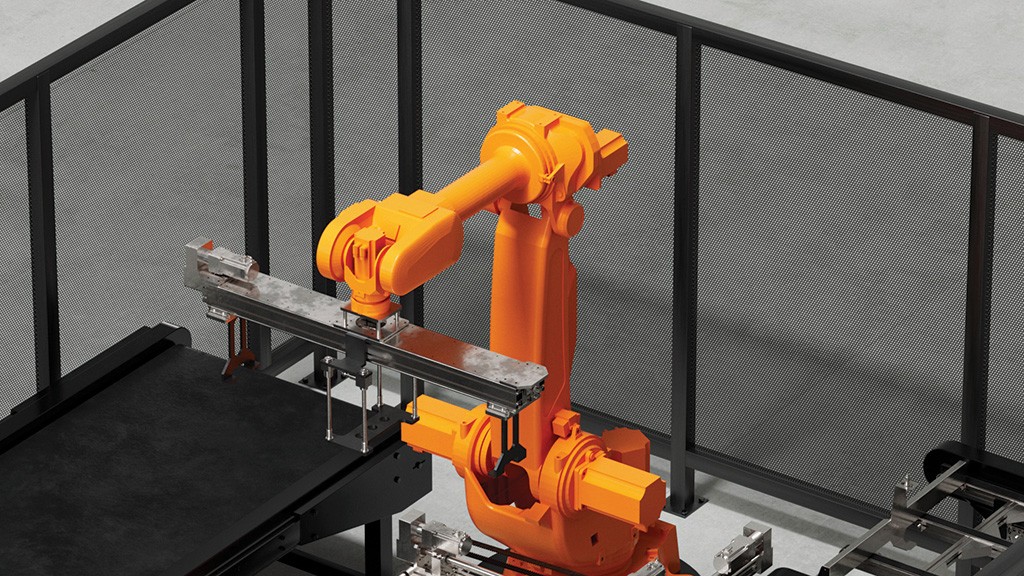

Robotics and artificial intelligence are invaluable tools to facilitate compliance with regulations, ensure legality, achieve economic sustainability, and promote best practices in the recycling and recovery of electronic waste. These cutting-edge technologies offer concrete solutions to address the challenges faced by the industry. Adapting and reinventing existing automation technologies for effective waste treatment processes poses a unique challenge.

Unlike the standardized processes used in manufacturing millions of identical objects, the recycling industry lacks standardization due to the diverse range of electronic devices. Each manufacturer designs and develops devices uniquely, making universal dismantling processes nearly impossible.

Consequently, shredding has been adopted as a faster and simpler method for material recovery, but it results in lower material yields and shredded waste that is contaminated with toxic substances. This is where the latest developments in robotics and artificial intelligence make a difference.

Robotics and AI's pivotal role in e-waste sorting and recovery

Robotics, computer vision, and artificial intelligence have extensive applications in the recycling of electronic waste. The true strength of AI lies in its ability to learn a decision-making process by studying a few examples, and then generalize and apply it to similar but unseen contexts.

Consider, for example, the process of unscrewing screws on the rear covers of flat-screen televisions. This step is necessary to remove the panel and recover the printed circuit boards inside. Each television will have screws of different colours, shapes, and positions on the device. Thanks to artificial intelligence, it is possible to teach the system the general concept of screws and enable the robot to recognize and locate the screws, even on television models it has never encountered before. This allows the robot to unscrew them autonomously and is the concept implemented in HIRO TEIA, HIRO Robotics' system for the treatment of flat-screen monitors and televisions.

Robots can also be used to classify and sort electronic boards based on the value of their components, optimizing material extraction. HIRO NISA, for example, employs a rapid delta robot to efficiently sort electronic boards into separate output bags.

Furthermore, robots can handle the disassembly of solar panels, which will constitute a significant portion of e-waste in the near future. They can also be utilized to identify lithium-ion batteries in mixed waste streams, reducing the risk of fires in recycling facilities. Another area where robots are poised to make a difference is the recycling of electric vehicle batteries, which are increasingly prevalent in the global market.

A sustainable future for electronic waste

There is an urgent need to make recycling processes economically viable. Approximately 83 percent of the 56 million metric tons of e-waste generated worldwide each year is currently untreated and improperly recycled, according to 2019 data from the Global E-Waste Monitor. By strengthening the capabilities of recycling plants through robotics and artificial intelligence, we can process more waste streams and recover a higher percentage of valuable materials. This will result in fewer exports of waste to underdeveloped countries or environmental dispersal, as well as a reduced environmental impact of traditional mining. Robotics and artificial intelligence truly hold the key to transforming electronic waste into a valuable resource for our communities.

Tomaso Manca is the co-founder and marketing director of HIRO Robotics, a producer of robotics for e-waste recycling.

Company info

Incubatore Bic Filse

Via Greto di Cornigliano 6r

Genova,

IT, 16152

Website:

hirorobotics.com/en/home